Reliability, Availability, Maintainability (RAM) Analysis and Fault-Tree Analysis (FTA)

RAM analysis is a tool that improves strategic decision-making by gaining a clear understanding of the impact of capital expenditure during front end engineering design or facility turn-around planning.

Major Benefits

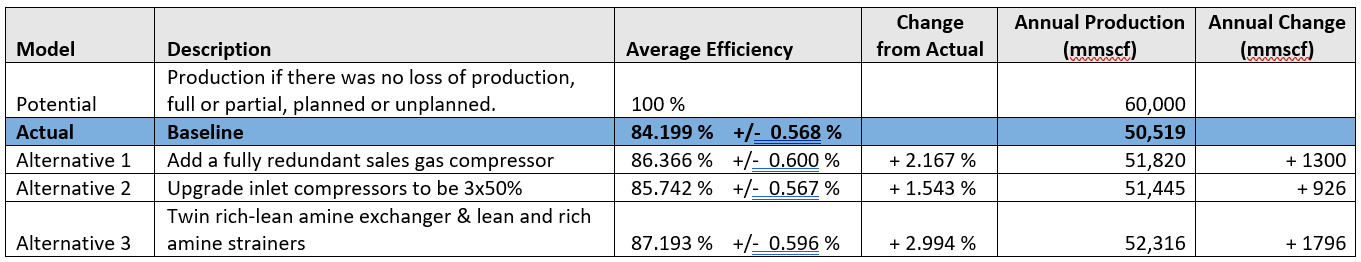

Determine plant efficiency

Optimize plant operations and identify areas for debottlenecking

Compare production values for different design options

How it works

RAM Analysis uses the following information from your major process equipment:

-Mean time to failure (MTTF)

-Mean time to repair (MTTR)

-Capacity loss on failure & repair

-Equipment redundancy

The efficiency of your facility is modelled using the Monte Carlo analytical method, to identify your actual production rate accounting for equipment failures and downtime. This identifies weak links in your facility holding it back from its maximum efficiency. The industry leading RAM analysis software Maros by DNV GL is used.